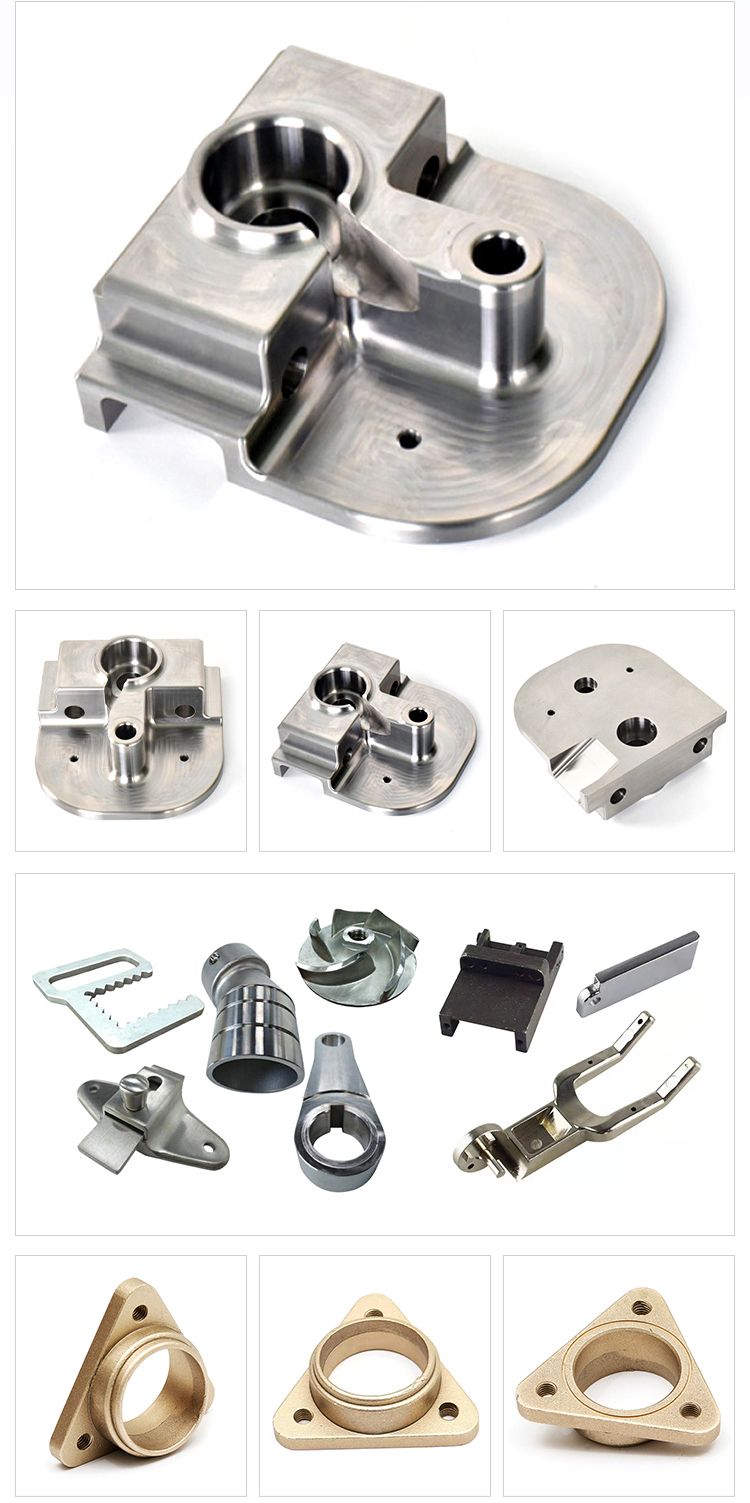

| process | sand casting, machining etc |

| Lead Time | 30-60 days after receiving your deposit,depending on quantity |

| Supply Ability | 15000 Ton/Tons per Year |

| application | Mechanical Parts, Vehicle, Agro Machinery, Pipe, Valves, etc |

| payment | Client negotiation |

| Specification | 1.Material: all gray iron,ductile iron grades. 2.Standard: ASTM,DIN,BS,JIS,GB. 3.Surface finish: Shot blasting,painting, machining, etc. 4.Weight: 0.1-3000kgs. |

| Production facility | 1.Casting facility: Furan resin sand molding line,Medium frequency induction furnace, Shot blasting machine 2.Machining facility: CNC, NC lathe,vertical lathe, boring machine, milling machine, other ordinary machine tools, linear cutting machine |

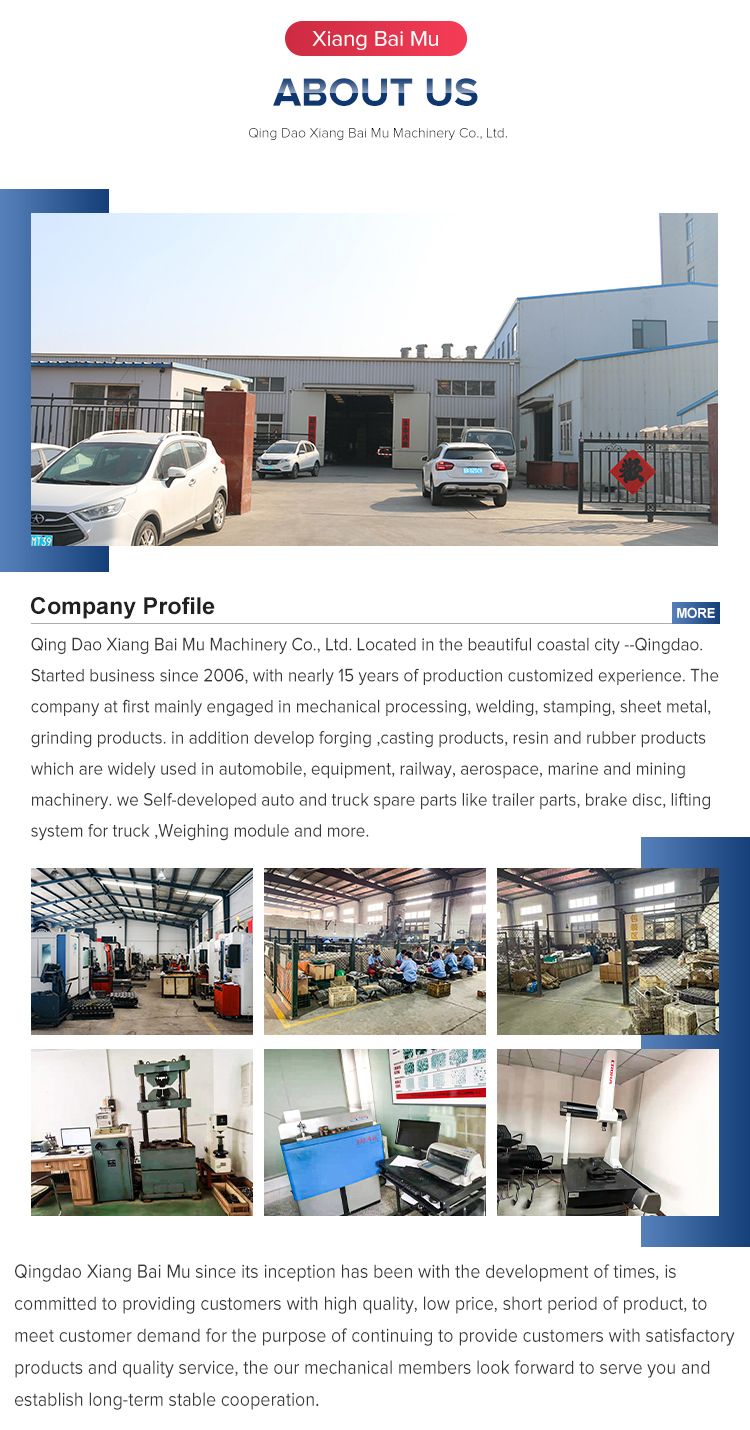

| place of origin | Qingdao, China |

| model number | with the drawing |

| standard | JIS, ANSI, DIN, BS, GB |